The Project Gutenberg EBook of The Dollar Hen, by Milo M. Hastings This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.net Title: The Dollar Hen Author: Milo M. Hastings Release Date: August 22, 2004 [EBook #13254] Language: English Character set encoding: ASCII *** START OF THIS PROJECT GUTENBERG EBOOK THE DOLLAR HEN *** Produced by Roger Taft, grandson of Milo Hastings, Jim Tinsley, and the Online Distributed Proofreading Team. [Transcriber's Note: This printing had more than its share of typographical errors. Obvious typos, like "tim" for "time", have been corrected.]

Twenty-five years ago there were in print hundreds of complete treatises on human diseases and the practice of medicine. Notwithstanding the size of the book-shelves or the high standing of the authorities, one might have read the entire medical library of that day and still have remained in ignorance of the fact that out-door life is a better cure for consumption than the contents of a drug store. The medical professor of 1885 may have gone prematurely to his grave because of ignorance of facts which are to-day the property of every intelligent man.

There are to-day on the book-shelves of agricultural colleges and public libraries, scores of complete works on "Poultry" and hundreds of minor writings on various phases of the industry. Let the would-be poultryman master this entire collection of literature and he is still in ignorance of facts and principles, a knowledge of which in better developed industries would be considered prime necessities for carrying on the business.

As a concrete illustration of the above statement, I want to point to a young man, intelligent, enterprising, industrious, and a graduate of the best known agricultural college poultry course in the country. This lad invested some $18,000 of his own and his friends' money in a poultry plant. The plant was built and the business conducted in accordance with the plans and principles of the recognized poultry authorities. To-day the young man is bravely facing the proposition of working on a salary in another business, to pay back the debts of honor resulting from his attempt to apply in practice the teaching of our agricultural colleges and our poultry bookshelves.

The experience just related did not prove disastrous from some single item of ignorance or oversight; the difficulty was that the cost of growing and marketing the product amounted to more than the receipts from its sale. This poultry farm, like the surgeon's operation, "was successful, but the patient died."

The writer's belief in the reality of the situation as above portrayed warrants him in publishing the present volume. Whether his criticism of poultry literature is founded on fact or fancy may, five years after the copyright date of this book, be told by any unbiased observer.

I have written this book for the purpose of assisting in placing the poultry business on a sound scientific and economic basis. The book does not pretend to be a complete encyclopedia of information concerning poultry, but treats only of those phases of poultry production and marketing upon which the financial success of the business depends.

The reader who is looking for information concerning fancy breeds, poultry shows, patent processes, patent foods, or patent methods, will be disappointed, for the object of this book is to help the poultryman to make money, not to spend it.

Unless the reader has picked up this volume out of idle curiosity, he will be one of the following individuals:

1. A farmer or would-be farmer, who is interested in poultry production as a portion of the work of general farming.

2. A poultryman or would-be poultryman, who wishes to make a business of producing poultry or eggs for sale as a food product or as breeding stock.

3. A person interested in poultry as a diversion and who enjoys losing a dollar on his chickens almost as well as earning one.

4. A man interested in poultry in the capacity of an editor, teacher or some one engaged as a manufacturer or dealer in merchandise the sale of which is dependent upon the welfare of the poultry industry.

To the reader of the fourth class I have no suggestions to make save such as he will find in the suggestions made to others.

To the reader of the third class I wish to say that if you are a shoe salesman, who has spent your evenings in a Brooklyn flat, drawing up plans for a poultry plant, I have only to apologize for any interference that this book may cause with your highly fascinating amusement.

To the poultryman already in the business, or to the man who is planning to engage in the business for reasons equivalent to those which would justify his entering other occupations of the semi-technical class, such as dairying, fruit growing or the manufacture of washing machines, I wish to say it is for you that "The Dollar Hen" is primarily written.

This book does not assume you to be a graduate of a technical school, but it does bring up discussions and use methods of illustration that may be unfamiliar to many readers. That such matter is introduced is because the subject requires it; and if it is confusing to the student he will do better to master it than to dodge it. Especially would I call your attention to the diagrams used in illustrating various statistics. Such diagrams are technically called "curves." They may at first seem mere crooked lines, if so I suggest that you get a series of figures in which you are interested, such as the daily egg yields of your own flock or your monthly food bills, and "plot" a few curves of your own. After you catch on you will be surprised at the greater ease with which the true meaning of a series of figures can be recognized when this graphic method is used.

I wish to call the farmer's attention to the fact that poultry keeping as an adjunct to general farming, especially to general farming in the Mississippi Valley, is quite a different proposition from poultry production as a regular business. Poultry keeping as a part of farm life and farm enterprise is a thing well worth while in any section of the United States, whereas poultry keeping, a separate occupation, requires special location and special conditions to make it profitable. I would suggest the farmer first read Chapter XVI, which is devoted to his special conditions. Later he may read the remainder of the book, but should again consult the part on farm poultry production before attempting to apply the more complicated methods to his own needs.

Chapter XVI, while written primarily for the farmer, is, because of the simplicity of its directions, the best general guide for the beginner in poultry keeping wherever he may be.

To the reader in general, I want to say, that the table of contents, a part of the book which most people never read, is in this volume so placed and so arranged that it cannot well be avoided. Read it before you begin the rest of the book, and use it then and thereafter in guiding you toward the facts that you at the time particularly want to know. Many people in starting to read a book find something in the first chapter which does not interest them and cast aside the work, often missing just the information they are seeking. The conspicuous arrangement of the contents is for the purpose of preventing such an occurrence in this case.

IS THERE MONEY IN THE POULTRY BUSINESS?

A Big Business; Growing Bigger

Less Ham and More Eggs

Who Gets the Hen Money?

WHAT BRANCH OF THE POULTRY BUSINESS?

Various Poultry Products

The Duck Business

Squabs Have Been Overdone

Turkeys not Adapted to Commercial Growing

Guinea Growing a New Venture

Geese, the Fame of Watertown

The Ill-omened Broiler Business

South Shore Roasters

Too Much Competition in Fancy Poultry

Egg Farming the Most Certain and Profitable

THE POULTRY PRODUCING COMMUNITY

Established Poultry Communities

Developing Poultry Communities

Will Co-operation Work?

Co-operative Egg Marketing in Denmark

Corporation or Co-operation

WHERE TO LOCATE

Some Poultry Geography

Chicken Climate

Suitable Soil

Marketing—Transportation

Availability of Water

A Few Statistics

THE DOLLAR HEN FARM

The Plan of Housing

The Feeding System

Water Systems

Out-door Accommodations

Equipment for Chick Rearing

Twenty-five Acre Poultry Farms

Five Acre Poultry Farms

INCUBATION

Fertility of Eggs

The Wisdom of the Egyptians

Principles of Incubation

Moisture and Evaporation

Ventilation—Carbon Dioxide

Turning Eggs

Cooling Eggs

Searching for the "Open Sesame" of Incubation

The Box Type of Incubator in Actual Use

The Future of Incubation

FEEDING

Conventional Food Chemistry

How the Hen Unbalances Balanced Rations

DISEASES

Don't Doctor Chickens

The Causes of Poultry Diseases

Chicken Cholera

Roup

Chicken-pox, Gapes, Limber-neck

Lice and Mites

POULTRY FLESH AND POULTRY FATTENING

Crate Fattening

Caponizing

MARKETING POULTRY CARCASSES

Farm Grown Chickens

The Special Poultry Plant

Suggestions From Other Countries

Cold Storage of Poultry

Drawn or Undrawn Fowls

Poultry Inspection

QUALITY IN EGGS

Grading Eggs

How Eggs are Spoiled

Egg Size Table

The Loss Due to Carelessness

Requisites of Producing High Grade Eggs

HOW EGGS ARE MARKETED

The Country Merchant

The Huckster

The Produce Buyer

The City Distribution of Eggs

Cold Storage of Eggs

Preserving Eggs Out of Cold Storage

Improved Methods of Marketing Farm-Grown Eggs

The High Grade Egg Business

Buying Eggs by Weight

The Retailing of Eggs by the Producer

The Price of Eggs

N.Y. Mercantile Exchange, Official Quotations

BREEDS OF CHICKENS

Breed Tests

The Hen's Ancestors

What Breed?

PRACTICAL AND SCIENTIFIC BREEDING

Breeding as an Art

Scientific Theories of Breeding

Breeding for Egg Production

EXPERIMENT STATION WORK

The Stations Leading in Poultry Work

The Story of the "Big Coon"

Important Experimental Results at the Illinois Station

Experimental Bias

The Egg Breeding Work at the Maine Station

POULTRY ON THE GENERAL FARM

Best Breeds for the Farm

Keep Only Workers

Hatching Chicks with Hens

Incubators on the Farm

Rearing Chicks

Feeding Laying Hens

Cleanliness

Farm Chicken Houses

The chicken business is big. No one knows how big it is and no one can find out. The reason it is hard to find out is because so many people are engaged in it and because the chicken crop is sold, not once a year, but a hundred times a year.

Statistics are guesses. True statistics are the sum of little guesses, but often figures published as statistics are big guesses by a guesser who is big enough to have his guess accepted.

A Big Business; Growing Bigger

The only real statistics for the poultry crop of the United States are those of the Federal Census. At this writing these statistics are nine years old and somewhat out of date. The value of poultry and eggs in 1899, according to the census figures, was $291,000,000. Is this too big or too little? I don't know. If the reader wishes to know let him imagine the census enumerator asking a farmer the value of the poultry and eggs which he has produced the previous year. Would the farmer's guess be too big or too small?

From these census figures as a base, estimates have been made for later years. The Secretary of Agriculture, or, speaking more accurately, a clerk in the Statistical Bureau of the Department of Agriculture, says the poultry and egg crop for 1907 was over $600,000,000.

The best two sources of information known to the writer by which this estimate may be checked are the receipts of the New York market and the annual "Value of Poultry and Eggs Sold," as given by the Kansas State Board of Agriculture.

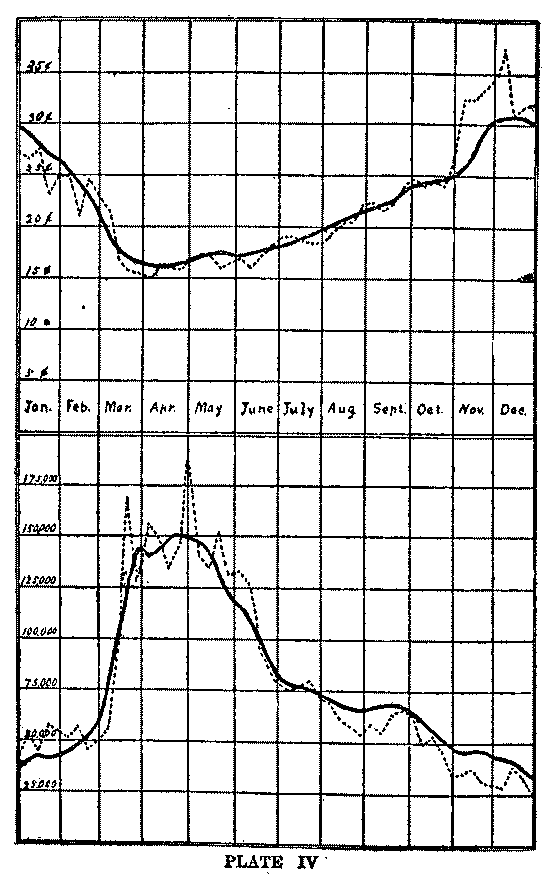

In plate I the top curve a-a gives the average spring price of Western first eggs in the New York market. The curve b-b gives the annual receipts of eggs at New York in millions of cases. Now, since value equals quantity multiplied by price, and since the quantity and values of poultry are closely correlated to those of eggs, the product of these two figures is a fair means of showing the rate of increase in the value of the poultry crop. Starting with the census value of $291,000,000 for the year 1899, we thus find that by 1907 the amount is very close to $700,000,000. This is represented by the lower line.

The value of the poultry and eggs sold in Kansas have increased as follows:

| Year | Value |

| 1903 | $ 6,498,856 |

| 1904 | 7,551,871 |

| 1905 | 8,541,153 |

| 1906 | 9,085,896 |

| 1907 | 10,300,082 |

The dotted line e-e represents the increase in the national poultry and egg crop estimated from the Kansas figures. Evidently the estimate given in Secretary Wilson's report was not excessive.

Now, I want to call the reader's attention to some relations about which there can be no doubt and which are even more significant. The straight line c-c in Plate 1 represents the rate of increase of population in this country. The line b-b represents the rate of increase in egg receipts at New York. As the country data backs up the New York figures, the conclusion is inevitable that the production of poultry and eggs is increasing much more rapidly than is our population.

"Over-production," I hear the pessimist cry, but unfortunately for Friend Pessimist, we have a gauge on the over-production idea that lays all fears to rest. When the supply of any commodity increases faster than the demand, we have over-production and falling prices. Vice-versa, under-production is shown by a rising price. That prices of poultry and eggs have risen and risen rapidly, has already been shown.

"But prices of all products have risen," says one. Very true, but by statistics with which I will not burden the reader, I find that prices of poultry products have risen more rapidly than the average rise in values of all commodities. This shows that poultry products are really more in demand and more valuable, not apparently so. Moreover, the rise in the price of poultry products has been much more pronounced than the average rise in the price of all food products, which proves the growing demand for poultry and eggs to be a real growing demand, not a turning to poultry products because of the high price of other foods, as is sometimes stated.

Less Ham and More Eggs.

Certainly we, as a nation, are rapidly becoming eaters of hens and of hen fruit. Reasons are not hard to find. Poultry and eggs are the most palatable, most wholesome, most convenient of foods. Our demands for the products of the poultry yard grows because we are learning to like them, and because our prosperity has grown and we can afford them.

Another reason that the consumption of eggs is growing is because the condition in which they reach the consumer is improving. The writer may say some pretty hard things in this work about the condition of poultry and eggs as they are now marketed, but any old-timer in the business will tell you stories of things as they used to be that will easily explain why our fathers ate more ham and less eggs.

Yet another reason why the per capita consumption of hens as measured in pounds or dollars increases, is that the hen herself has increased in size; whereas John when he was Johnnie ate a two-ounce drumstick, now Johnnie eats an analogous piece that weighs three ounces. Perhaps, also, we have a growing respect for the law of Moses, or may be vegetarians who think that eggs grow on egg plants are becoming more numerous.

Our consumption of pork per capita has, in the last half century, diminished by half, our consumption of beef has remained stationary, but our consumption of poultry and eggs has doubled itself, we know not how many times, for a half century ago the ancestor of the industrious hen of this age serenely scratched up grandmother's geraniums and was unmolested by the statisticians.

Who Gets the Hen Money?

Seven hundred millions of dollars is a lot of money. Who gets it? There are no Rockefellers or Armours in the hen business. It is the people's business. Why? Because the nature of the business is such that it cannot be centralized. Land and intelligent labor, prompted by the spirit of ownership, is necessary to succeed in the hen business. Land the captains of industry have not monopolized, and labor imbued with the spirit of ownership they cannot monopolize. The chicken business is, in dollars, one of the biggest industries in the country. In numbers of those engaged in it, the chicken business is the biggest industry in the world—I bar none. Why is this true? Primarily because the hen is a natural part of the equipment of every farm and of many village homes as well. It is these millions of small flocks that count up in dollars and men and give such an immense aggregate.

More than ninety-eight per cent. of the poultry and eggs of the country are produced on the general farm. The remaining one or two per cent. are produced on farms or plants where chicken culture is the cash crop or chief business of the farmer. It is this business, relatively small, though actually a matter of millions, that is commonly spoken of as the poultry business, and about which our chief interest centers. A farmer can disregard all knowledge and all progress and still keep chickens, but the man who has no other means of a livelihood must produce chicken products efficiently, or fail altogether—hence the greater interest in this portion of the industry.

The poultry business as a business to occupy a man's time and earn him a livelihood, is a thing of recent origin and was little heard of before 1890. Since that time it has undergone a somewhat painful, though steady growth. Many people have lost money in the business and have given it up in disgust, but on a whole the business has progressed wonderfully, and now shows features of development that are clearly beyond the experimental stage and are undoubtedly here to stay.

The suggestion has been made by those who have failed or have seen others fail in the poultry business, that success was impossible because of the destructive competition of the farmer, whose expense of production is small. Herein lies a great truth and a great error. The farmer's cost of production is small, much smaller than that on most of the book-made poultry farms—but the inference that the poultryman's cost of production cannot be lowered below that of the farmer is a different statement.

The farm of our grandfather was a very diversified institution. It contained in miniature a woolen mill, a packing house, a cheese factory, perhaps a shoe factory and a blacksmith shop. One by one these industries have been withdrawn from general farm-life, and established as independent businesses. Likewise our dairy farms, our fruit farms, and our market gardens have been segregated from the general farm. This simply means that manufacturing cloth, or cheese, or producing milk, or tomatoes can be done at less cost in separate establishments than upon a general farm.

The general farm will always grow poultry for home consumption, and will always have some surplus to sell. With the surplus, the poultryman must compete. His only hope of successful competition is production at lower cost. Can this be done? It is being done, and the numbers of people who are doing it are increasing, but they spend little money at poultry shows, or with the advertisers of poultry papers, and hence are little heard of in the poultry world.

The people whose names and faces are in the poultry papers are frequently there only while their money lasts. They write long articles and show pictures of many houses and yards to prove that there is money in the poultry business, but if one should keep their names and put the question to them five years hence, a great many could say, "Yes, there is money in the poultry business; mine is in it."

Such people and such plants do not get the cost of production down below the farmer's level. Between these two classes of poultry plants, the writer hopes in this work to show the distinction.

The chicken business is especially prone to failure from a disregard of the common essential relation of cost and selling price necessary to the success of any business. That this should be more true of the poultry business than of any other undertakings is to be explained by the facts that as a business, it is new, that many of those who engage in it are inexperienced, but most particularly because practically all the literature published on the subject has been written by or written in the interest of those who had something to sell to the poultryman. As a result the figures of production are generally given higher than the facts warrant. The investor, be he ever so shrewd a man, builds upon these promises and when he finds his production lower, is caught with an excessive investment and a complicated system on his hands, which make all profits impossible and which cannot readily be adapted to the new conditions.

Estimates of poultry profits are quite common, but there are few published figures showing the results that are actually obtained under practical working conditions. In this volume I will try to give the facts of what is being and can be actually accomplished.

Various Poultry Products.

In considering the poultry industry we must first get some idea of the various articles produced for sale.

It is common knowledge that the large meat packer can undersell the small packer because the by-products, such as bristles, which are wasted by the local killer, are a source of income to the large packer. Now, this does not infer that the small packer is shiftless and neglects to save his bristles, but that on the scale on which he operates it would cost him more to save the bristles than he could realize on them.

So it is with poultry farming. For illustration: A visionary writer in a leading poultry paper, not long ago, advised poultrymen to store eggs. In reality this would be the height of folly, unless the poultryman had his own retail store. In the first place profit on cold storage eggs, when all expenses are paid, will not average a half a cent a dozen; in the second place, the small lot would be relatively troublesome and expensive to handle, and in the third place, small lots of cold storage eggs are looked upon with suspicion and do not find ready sale. So we see that cold storage eggs are not a suitable product for the small poultryman to handle.

A second illustration of an ill-chosen combination might be taken in the case of a duck farmer who attempts to produce broilers. The principal difficulty of the duck business is that of getting sufficient intelligent labor in the rush season. The chief expense of investment is for incubators and brooder houses. If the duck farmer now tries to add broilers, he will find that the labor comes at the same time of the year, that the chief equipment required is that which is already crowded by the duck business, and that of the men who have succeeded moderately well in caring for ducks will fail altogether with the young chicks, which do not thrive under the same machine-like methods.

On the other hand, let us take the example of an egg farm man who has resolved to combine his attention wholly to the production of market eggs. He succeeds well in his work and is visited by the poultry editors. His picture, the picture of his chickens and of his chicken houses, are printed in the poultry papers. For a reasonable sum invested in advertising and in exhibition at the shows, this man could now double his income by going into the breeding stock business. To refuse to spread out in this case would certainly be foolish.

The following classification of the sales products of the poultry industry is given as a basis for farther consideration.

For food purposes:

Eggs.

Hens, after laying has been finished.

Cockerels, necessarily hatched in hatching pullets for layers. (Sold as squab broilers, regular broilers, springs, roasters or capons.)

Both sexes as squab broilers, broilers or roasters.

For stock purposes:

Eggs for hatching.

Day-old chicks.

Mature fowls.

For table—green or spring ducks.

By-products, old ducks and duck feathers.

For breeding-stock.

I will now discuss these products more in detail. Poultry, other than chickens, I do not care to discuss at length, because it is not for the purpose of the book, and because the demand for other kinds of poultry is limited and the chance for the growth of the business small.

The Duck Business.

The duck business is the most highly commercialized at the present time of any branch of the poultry business. The duck is the oldest domestic bird and was hatched by artificial incubation in China, when our ancestors were gnawing raw bones in the caves of Europe. The duck is the most domestic of birds and will thrive under more machine-like methods and without that touch of nature and of the owner's kindly interest so necessary to the welfare of the fowls of the gallinaceous order. The green duck business is about twenty years old and has become an established business in every sense of the word. The largest plants now produce about one hundred thousand ducks per annum. The profits at present are not large even for the most successful plants, because the demand is limited and the production has reached such a point that cost of production and selling price bear a definite relation as in all established businesses. The green duck business is not an easy one for the novice because the margin between cost (chiefly food cost) and selling price is low, and unless the new man can reduce the cost of production or raise his selling price in some way, he will have no advantage over the old and successful firms.

Squab Business Overdone.

The business of producing pigeon squabs resembles the duck business in the sense that it has been reduced to a successful system. The production of squabs has grown until the demand is satisfied and the price has fallen to just that figure that will continue to bring in a sufficient number of squabs from the plants which are already established, or which continue to be established by those who do not stop to investigate the relation between the cost of production and the prevailing prices.

Turkeys Not a Commercial Success.

In the case of turkeys, we find exactly opposite conditions. The price of turkeys has risen with the price of chickens and eggs, until one would think that there would be great money in the business, and there is, for the motherly farm wife who has the knack of bringing the little turks through the danger of delicate babyhood. But just as the duck is more domesticated than the chicken, so the turkey, which yet closely resembles its wild ancestor, is less domestic and has as yet failed to surrender to the ways of commercial reasoning, the chief factor of which is artificial brooding.

The presence of a disease called blackhead has done vast injury to the turkey industry in the northeastern section of the country. In the South the industry has been booming. Especially in Tennessee and Texas, I found great local pride in the turkey crop. I certainly would advise any farm wife, in sections where blackhead does not prevail, to try her hand at turkey raising. As to her advisability of continuance in the business, the number of turkeys at the end of the season will be the best judge.

Guinea Growing a New Venture.

The guinea growing business is the newest of the poultry industries. In fact, it may be said of guineas, as of our grandmother's tomatoes, "Folks had them around without knowing they were of any use." The new use for guineas is as a substitute for game. Guinea broilers make quail-on-toast and older ones are good for grouse, prairie chicken or pheasant. The retail price in the large cities runs as high as $1.50 to $2.00 a pair. It will probably not pay to raise them unless one is sure of receiving as much as 50 cents each. As for the rearing of guineas, they may be considered on a parallel case with turkeys, if anything they are even more difficult to raise in large quantities. I would also advise this additional precaution: Look up the market in the locality before attempting guinea rearing.

Geese—the Fame of Watertown.

As for the goose business, the writer must admit that he doesn't know much about it. In fact, the most of my knowledge concerning this business was acquired by a visit to Watertown, Wis., which is the center of the noodled goose industry

The Watertown geese are fed by hand every two hours day and night. They sell to the Hebrew trade at as much per pound as the goose weighs, and have brought as high as $14.00 apiece. All of this is interesting, but I hold that the reader who is willing to take instruction will do better to be guided toward those branches of the poultry industry for the products of which there is a great and increasing demand. So we will leave the goose and guinea business to the venturesome spirits and consider the various branches of the chicken industry.

The Ill-omened Broiler Business.

The broiler business stands to-day as the ill-omened valley in the poultry landscape. As a rule broiler production has not and probably will not pay. I know of a few exceptions—about enough to prove the rule.

Most poultry writers, when they make the statement that broilers do not pay, insert the phrase "As an exclusive business" after the word broilers. This is merely a ruse to take the rough edge off an unpleasant statement, for it certainly hurts the poultry editor to admit that a much exploited branch of the industry is a failure. Nevertheless it is a failure and the more frankly we admit the fact, the less good capital and good brains will be wasted in the attempt to produce at a profit something which is, and probably always will be, produced at a loss.

The reason the broiler is produced at a loss is that 95 per cent. of the broilers produced are a by-product of egg, fancy and general poultry production, and as such their selling price is not determined by the cost of production, or the supply determined by the demand. That the broiler business received the boom that it did, is due to plain ignorance of the cost of production, or to the appreciation that the ability to rear young chicks could find a more profitable outlet than in broiler production. Let us take an analogous case. Suppose a city man should discover the fact that there was a demand for dried casein from skim milk. With pencil and paper he could easily figure profits in the business. If this dreamer would attempt to keep cows for the production of casein and throw away his butter fat, we would have an analogous case to the broiler raiser who does not keep his pullets for egg production.

The young cockerel, like skim milk, is a by-product and may pay over the cost of feeding, or some other specific item, but that he does not pay the whole cost, including wages for the manager is proven by two facts: First, every large broiler plant yet started has either failed flatly or shifted its main line to other things; second, egg farmers would be only too glad to buy pullets at the price for which they sell the cockerels—a confession that it costs more to produce broilers than they will bring.

The conception of the broiler business when it was boomed twenty years ago was to produce broilers in early spring, when other folks had none. It was, like the early watermelon, or the early strawberry business—to make its profits in extreme prices.

This idea received several severe blows from the hands of modern progress. One is the development of poultry fattening and crate feeding in this country. This has resulted in supplying the consumer with choice chicken-flesh that can be produced more economically than broilers. Formerly it was a case of eating old hen—rooster, age unknown, or broilers—now we have capon, roaster, crate-fattened chickens and green ducks, all rivals for the place formerly occupied exclusively by the broiler.

Again, the improvement of shipping and dressing facilities, the universal introduction of the refrigerator car and the introduction into the central west of the American breeds, has flooded the eastern market with a large amount of spring chickens—by-products of the egg business on the farm—which are almost equal in quality to the down-eastern product.

The most prominent reason of the lessened profit in broilers is the development of the cold storage industry. Cold storage destroys the element of season, and allows only that margin of profit that the consumer is willing to pay for a fresh killed broiler from a Jersey broiler plant, as compared with last summer's product from the Iowa farms. From a summer copy of Farm Poultry, I quote the Boston market:

| Fresh killed Northern and Eastern: | ||

| Fowls, choice | 15c | |

| Broilers, choice to fancy | 23-25c | |

| Western, ice packed: | ||

| Fowls, choice | 14c | |

| Broilers, choice | 20-22c | |

| Western frozen: | ||

| Fowls, choice | 14c | |

| Broilers, choice | 18-20c | |

| Eggs: | ||

| Nearly fancy | 26c | |

| Western choice | 17-1/2--18-1/2c | |

To complete our comparison I turn to the previous winter and find that the best storage eggs are quoted at 19c, when the best fresh are selling at 35c. This was a poor storage season and a quotation of 22c and 25c would perhaps be a fairer comparative figure. We find the per cent. of premium on the local product to be:

| Fowls, local over fresh western | 7 per cent. |

| Fowls, local over frozen western | 7 per cent. |

| Broilers, local over fresh western | 14 per cent. |

| Broilers, local over frozen western | 26 per cent. |

| Eggs, local over fresh western | 30 per cent. |

| Eggs, local over storage western | 37 per cent. |

I consider these general facts concerning the failure of broiler production, and the logical explanations given, as far more convincing than any figures I could give concerning the detailed cost of production. Nor am I capable of giving as accurate figures as I can in the case of poultry keeping for egg production, for I have had neither the desire nor the opportunity to look them up. The following suggestive analysis I submit for the purpose of pointing out why the cost of production is too great to allow a profit. We may consider the chick marketing as May, the weight as 1-1/4, and the price as 35 cents a pound, or, putting it roundly a price of 50 cents a bird.

Now, May broilers mean February eggs. If the reader will refer to the tables of hatchability and mortality he will see that for our northern states this is one of the worst seasons for hatching. A hatchability of 40 per cent. times a liveability of 50 per cent. gives a net liveability of 20 per cent. Now, anyone with the ability to produce high grade eggs at that time a year, could get about 40c a dozen for them, which raises the egg cost per broiler to about 17 cents. The feed cost per broiler is small, usually estimated at 12 cents, and this makes a cost of 29 cents. Now, let us allow a cent for expense of selling charges and forget all about investment, fuel and incidentals, we have left a margin of 20 cents.

Before going farther let us look at the labor bill. Suppose it is a one-man plant. Suppose the owner sets a value on his services of $1,200 per annum. That is pretty good, but few men who set a lower value on their services will have accumulated enough capital to go into the business. At 20 cents each it will take 6,000 broilers to make $1,200. That will take 30,000 eggs and at three settings will require 40 240-egg incubators, which, of a good make, will cost $1,260. To spread the hatching out over a longer period is to run into cheap prices on the one hand, or a still impossible egg season on the other. It will take upwards of a hundred brooders to house the chicks.

There is no use of going farther till we have solved these difficulties. First we have more work than one man can do; second, we require a number of hatchable eggs that cannot be bought in winter without a campaign of advertising and canvassing for them, that would make them cost double our previous figure. To produce them oneself would require a flock of 2,500 hens. When a man gets to that point in the business he is out of the broiler business and an egg farmer, and will do the same thing, hatch the chicks when eggs are cheap and fertile, selling his surplus cockerels for 25 cents each and permit the storage man to freeze them until the following spring to compete with the broiler man's expensively produced goods.

The effort at early broiler production was a natural result of the combination of the idea of artificial incubation with our grandmother's pride in having the first setting hen. But in the present age the man who attempts it is rowing against the current of economical production, for the cheaply produced broiler can be stored until the season of scarcity, with but slight loss in quality. To produce broilers in the season of scarcity, necessitates the consumption of a product (eggs) which cannot be so successfully stored, with a lesser quantity of that same product in its season of plenty. We will give the production of broilers no further attention save as a by-product of egg production.

South Shore Roaster.

The production of South Shore soft roasters in a local section of Massachusetts, offers a successful contrast with the broiler business and is, so far as the writer knows, the only case in the United States where pullets are profitably diverted from egg production. The process of roaster production is essentially as follows:

The incubators are set in the fall or early winter, and the chicks reared in brooder houses. As soon as the tender age is past, the chickens are put in simple colony houses where, with hopper fed corn, beef scrap and rye on the range, they grow throughout the winter and spring. They are sold from May 1st to July 1st and bring such prices that the cockerels are caponized yet not sold as capons, showing them to be the highest priced chicken flesh in the market save small broilers. Now, the income of roasters is two to five times as much per head as that of broilers. The added expense is only a matter of feed, which bears about the same ratio to weight as with broilers. The great advantage of the roaster business over that of the broiler business comes in the following points:

1st: The initial expense of eggs, incubation and brooding are distributed over a much larger final valuation.

2nd: The incubation period, while perhaps in as difficult a season, can be distributed over a longer period of time.

With 8 pound roasters at 30 cents, we have an expense account about as follows: cost of production to broiler stage, 30 cents as previously given. An additional food cost of 10 cents per pound of chicken flesh would still leave a margin of $1.40, so, for an income of $1,200, only about 860 birds need be raised, a proposition not beyond the capacity of one man to handle.

Allowing a spread of five hatching periods, the number of eggs required at once would be one-twelfth that demanded by the broiler farm. As it is, the roaster grower finds trouble in getting good eggs and is obliged to pay 50 cents a dozen for them, but his want is within the region of possibility.

The South Shore roaster district is an example of an industry built up by specialization and co-operation. But in this sense I do not mean co-operation in production, but that the product is handled by a few dealers and has become well known so that the brand sells readily at an advanced price. To a beginner in the South Shore district, the numerous successes and failures around him cannot help but be of great benefit. The South Shore roaster district of Massachusetts is the best example of specialized community production of poultry flesh that we have in the United States. It is only rivaled by the districts in the south of England and in France.

In Chapter III the writer takes up fully the community production of eggs. The reason I have gone into this matter in regard to eggs rather than roasters, is because the egg production is much the greater industry, and, whereas the soft roaster is at a premium only in a few Boston shops, high grade eggs are universally recognized and in demand. Many of the economies, especially concerning incubation, would apply equally well in both communities. I expect to see the time when chicken flesh shall be produced with these more advanced methods in many "South Shore" communities.

Too Much Competition in Fancy Poultry.

The various types of chicken farming are classified by what is made the leading sales product. This will depend wholly upon what is done with the female chicks that are hatched. If they are sold as broilers it is a broiler plant; if as roasters, it is a roaster plant; if as stock, it is a fancy or breeding stock business, but if kept for laying the proposition is an egg farm, and all other products are by-products. These by-products are to be carefully considered, and sold at the greatest possible price, but their production is incidental to the production of the main crop.

Of the fancy poultry business as a main issue it must be said that it is certainly a poor policy to start out to make a living doing what hundreds of other people are only too glad to spend money in doing. Just as a homeless girl in a great city is beaten out in the struggle for existence by competition with girls who have good homes, and are working for chocolate money, so the man starting out as a poultry fancier is certainly working at great odds in competition with the professional men, farmers and poultry raisers whose income from fancy stock is meant to buy Christmas presents and not to pay grocery bills.

To enter the fancy poultry business, one should take up poultry breeding in a small way, while working at another occupation, or he may take up commercial poultry production, learn to produce stock in large quantities and at a low productive cost, after which any breeding stock business he may secure will be added profit. The fancier will find the cost of production as given for commercial purposes very instructive, but if he operates in a small way he should expect to find his productive costs increased unless he chooses to count his own labor as of little or no value. That every chicken fancier also has in a small way commercial products to sell, goes without saying. These, indeed, together with his sales of high-priced stock, may pull him through with a total profit, even though his production cost is great, but every fancier should take a pride in making the sales at commercial rates pay for their cost of production.

If the reader has received the impression from the present discussion that fancy poultry breeding always proves unprofitable, he certainly has failed to get the key-note of the situation. There are numbers of fancy poultry breeders making incomes of several thousand dollars per year, but these are old breeders and well-known men.

There is another type of poultry fancier who is more commercial in his methods, but whose work lacks the personal enthusiasm and artistic touch of the regular fancier. I refer to the band wagon style of breeder who gets out a general catalog in which are pictured acres of poultry yards with fences as straight as the draughtsman's rule can make them. Such men do a big business. They may carry a part or all of the breeding stock on a central poultry plant and farm out the eggs, contracting to buy back the stock in the fall, or the poultry farm may be a myth and the manager may simply sell the product of the neighboring farmers who raise it under contract.

The system is naturally disliked by the higher class fanciers, but the writer must confess that any system which gets improved stock distributed among the farmers is worthy of praise. These types of poultry farms have been more largely carried on in the West than in the East, owing to the fact that true fanciers are thicker in the East. There is undoubtedly still plenty of room for band wagon poultry plants in the West and especially in the South.

As adjuncts of this business may be mentioned the sale of a line of poultry supplies and the handling of other pet stock, such as dogs or Shetland ponies. In this case the advantage of such additions depends upon the fact that the greatest cost is that of advertising, and, if anything that will be associated in the buyer's mind with the main article be added to the catalog, it will result in additional sales at a low rate of advertising cost.

Egg Farming the Most Certain and Profitable.

We have now discussed all the branches of the poultry business save that of egg production, and the result of our review indicates that most of these fields are either of limited opportunities or that they present obstacles in the very nature of the work that prevent their being conducted on a large scale.

Egg production is undoubtedly the most promising and profitable branch of the poultry industries. The chief reason that this is true is to be found in the fact that the most difficult feature in chicken growing is the rearing of young stock through the brooding period. Now, as the eggs laid by a hen are worth several times the value of her carcass, it stands to reason that once we succeed in rearing pullets, egg farming must be the most profitable business to engage in.

For each hen that passes through a laying period there is her own carcass, and at least one cockerel, that are necessarily produced and that must be marketed. Now, the pullet is worth more for egg producing than can be realized for her as a broiler or roaster, and her extra worth may be considered as counter-balancing the price at which cockerels must be sold.

The egg crop represents about two-thirds of the value of all poultry products, and the demand for the high grade goods has never been satisfied. Egg farming cannot easily be overdone, whereas any other type of poultry production must compete with the cockerels and hens that are a by-product of egg farming.

Egg farming by no means relieves one from the difficulties of incubation and growing young stock, but it does throw these difficult parts of the business at the natural season of the year and results in a distribution of work throughout a longer period of time.

In the remainder of the volume we will consider the poultryman as an egg farmer. We will also, unless otherwise stated, assume that he is a White Leghorn egg farmer, who is hatching by artificial incubation. Such reference to the marketing of poultry flesh or to other breeds will be made only in comparison of this type of the business or in relation to the production or handling of farm-grown poultry.

The builder of air castles in Poultrydom invariably starts out with a resumé of the specialization of the world's work and the wonderful advances in the economy of production of the large corporate organization, compared with the individual producer.

The lone blacksmith hammering out a horseshoe nail is contrasted with the mills of the American Steel Company. The fond dreamer looks upon the steel trust, the oil trust, the department store, the packing house, the chain groceries, the theatrical trust, and the colossal enterprises that dominate every field of industry save agriculture. Here, then, lies the neglected opportunity for the industrial dreamer to hop over the fence, awaken the sleeping farmer, and fill his own purse with the wealth to be made by applying modern business methods to agriculture.

The knowing smile—the farmer may be asleep and he may not be. Suppose that he is, does the fond dreamer dream that he is the first man from the industrial kingdom of great things to look with hungry eyes at the rich field of agricultural opportunity, basking in last century's sun? Alas, fond dreamer, your name is legion. Every farmer who has sent a son to college has known you and the Hon. William Jennings Bryan has met you, called you an agriculturist and defined you as a man who makes his money in town and spends it in the country.

But the dreamer is right in his first premise—great economies in production are the result of specialization and combination. Why not then in agriculture? I'll tell you why. There is a touch of nature in the living thing that calls for a closer interest on the part of the laborer than the industrial system of the mine and factory can give.

Why is combined and specialized production more economical? It may be because it gets more efficient work out of labor, it may be that larger operations make feasible the employment of more efficient methods and machinery. The cost of production may be lowered, by either or both of these means, or it may be lowered by an increased efficiency in machinery, even with a decreased efficiency in labor.

Combination and specialization so commonly cut down expenses because of large operations and the use of better tools, that we may take this saving for granted. When it comes to labor there is a different story. The negro working with boss and gang, or the machine-tender in the factory work as well or better for large than for small concerns, but the labor of a poultry plant is different. It is made up of a great many different operations well scattered in space and time. For the most part it is simple labor, but it is essential that it be performed with reasonable concern for the welfare of the business.

In other industries, as with men working at a bench, the presence of a foreman keeps them busy and their work may be daily inspected. To have foremen in poultry work would require as many foremen as laborers, and even then they would be as useless, for when the last round of the brooders is made at night a foreman standing three feet away could not know whether the laborer who had placed his hand in the brooder had found all well or all wrong.

It is useless to carry the argument farther. The labor bill is one of the biggest items of expense in poultry production. With a system where the efficiency of the labor decreases with the size of the business, large industrial enterprises are impossible. Such savings as will be made in buying supplies, selling, etc., will be wasted in the reduced efficiency of labor.

The bulk of labor in poultry work must be self-reliant labor and the only test for such efficiency is number of chicks reared and the weight of the egg basket. Even this will not be a complete test unless from the income be subtracted the feed bills.

A system of renting or working on shares that will gain the advantages of centralization without losing the individual interest of the laborer, will go a long way toward making the poultry business one wherein large capital and large brains can find a place to work. I expect to see in the future some such system evolved. In fact we have to-day a profit-sharing plan between owner and foreman on many of our best plants. To extend such to each laborer requires more system and better superintendence, but it is feasible and must come. But, better still is it for the worker to own the stock. Best yet if he owns both stock and land, leaving to larger capital only such phases of the business as involve great saving when done on a wholesale basis.

Just as the manufacturer of farm machinery, the packing of meat and the manufacture of butter have successfully been taken out of the control of the individual farmer and placed under corporate or co-operative organization, so the writer expects to see certain portions of the process of poultry production removed from the hands of the farmer and controlled by more specialized and expert labor. Far from meaning the lessening of the earning power of the farmer, every one of such steps means larger production and more profits. The ideal of agricultural economics is to give the farmer the smallest possible proportion of the work of agricultural production in order that the most may be produced and the farmer's share along with the others may be largest.

Established Poultry Communities.

In a previous chapter we spoke of the South Shore roaster district of Massachusetts. Here is a community where, in lots of from a dozen to four or five thousand, are annually produced seventy-five or one hundred thousand market fowls of one particular type. While this business was not built up by the efforts of a corporation or individual who planned definitely the entire project, yet we find a central influence at work in the person of the firm of Curtis Bros., who for years have bought the majority of South Shore roasters, and who have done a great deal to advertise the product and encourage their neighbors to a larger and more uniform production.

At Little Compton, R. I., is a very similar parallel of the South Shore district in the shape of egg farms. Here we find within a radius of two miles about one hundred thousand Rhode Island Red hens owned in flocks of two thousand or less. The methods used throughout the community are all alike and are simple in the extreme. There are no incubators, no brooders, no poultry houses, no long houses, no dropping boards to be scraped every morning, nothing in fact, but board-walled, board-roofed, colony houses, scattered over the grass fields and similar though smaller fields covered with coops for hens and chicks. Feeding is equally simple; a mash of meat, vegetables and ground grain mixed once a day and hauled around in a one-horse cart and hoppers of whole corn exposed in the houses. The houses are cleaned twice a year. Little Compton is, indeed, a community where all the rules of the poultry books are regularly violated, and yet a larger number of successful egg farms can be seen from the church spire at Little Compton Corners than most poultry writers have ever seen or read about. Strange it is, as Josh Billings puts it, that "some folks know things that ain't so."

An illustration published in a recent issue of the World's Work tells a remarkable story. A pile of egg shells as big as a straw stack certainly indicates "something doing" in the chicken business, and it is a very proud monument to Mr. Byce who, some twenty odd years ago, established an incubator factory at the town of Petaluma. Petaluma is in Sonoma County, California, forty miles north of San Francisco. In the census year of 1899, Sonoma County produced more eggs than any other county in the United States. To-day there are in the Petaluma region close to one million hens.

Like the Little Compton district, Petaluma is a one-breed community, White Leghorns being the breed used. The individual flocks range larger than at Little Compton, chiefly because the milder climate, smaller breed, and establishment of the central hatchery enables one man to take care of more birds.

When I asked Mr. Byce for a list of the people in his neighborhood keeping over one thousand hens, he replied by sending me a list of twenty-two men who keep from 8,000 down to 2,500 each, and said that to give those keeping from one to two thousand, would practically be to take a census of the county. The methods of housing and feeding used are simple and inexpensive like those at Little Compton.

The chief reason why Petaluma shows a more advanced development in the poultry community than the eastern poultry growing localities, is to be found in the climatic advantages which favor incubation (see Chapter on Incubation) and the consequent development of the central hatchery. Outside of this, the location is not especially favorable. The temperature is milder in the winter than in the East, but the Petaluma winter is one of continual rain which develops roup to a greater extent than we have it in the East. The prices received for high grade eggs in San Francisco is in the winter about equal to the top prices in New York. In the spring and summer New York will give more for fancy goods. The cost of corn on the Pacific Coast is about 40 cents a hundred more than on the Atlantic Coast. Wheat, however, is cheaper than in the East, but not cheap enough to substitute for the more staple grain.

The eggs from the Petaluma region are at present marketed largely through a co-operative marketing association.

Developing Poultry Communities.

I have shown why the large individual poultry farms with hired labor have not proven profitable fields for the investment of capital. Again, I have shown that in a few localities where the business was incidentally started, communities of independent poultry farmers have grown up which are very successful, and that there is no apparent reason why similar communities elsewhere, if intelligently located, could not do as well or better.

This looks like an excellent field for corporate enterprise. Certainly there is no more reason why the poultry community cannot be as successfully promoted as an irrigation project, or a cheese factory, or a trucking community. In such a community there are many functions that can be better performed by a capitalized body managed by experts than by individual poultrymen acting alone.

These functions are:

First, the selection of a location and the purchase of the land in large quantities.

Second, laying out this land into suitable individual holdings, with regard to economy of water supply and the collection of the product.

Third, the partial or complete equipment of these farms at less expense and in a more suitable manner than could or would be done by the individual holders.

Fourth, the sale or rent of these places to poultrymen at a reasonable profit on the investment, but at a rate which will still be below the cost at which the individual could have acquired the land. Fifth, the selection of the stock that would not only be better adapted to the enterprise than that which would be acquired by the individual farmer, but would possess the uniformity necessary to the maintenance of a standard grade in the product.

Sixth, the centralized hatching of the chicks by which means chicks can be more cheaply hatched and better hatched than by the imperfect methods available to the small poultryman.

Seventh, the purchase of all outside supplies with the usual savings involved in large purchases.

Eighth, a teaming system of delivering such supplies.

Ninth, a general protection against thieves and predatory animals by an organized war on all "varments."

Tenth, maintenance of the best methods in feeding and care by the employment of skilled advisers, or the operation of demonstration farms under the direction of the central management.

Eleventh, the enforced daily gathering of all eggs and their lodgment that same evening in a clean, dry cooler, with a thermometer hovering around 29 degrees Fahrenheit.

Twelfth, the strict enforcement of penalties against the man who attempts to sell bad eggs.

Thirteenth, the prompt dispatch of the product to its final market.

Fourteenth, the final sale of the eggs with opportunities for fancy prices made possible by an absolutely guaranteed product in quantities sufficient to permit of a regular supply and of advertising the product.

Fifteenth, the conduction of breeding operations along any desired line, with the opportunity of combining the principle of great numbers for selection with the comparison of all progeny from ancestry, a method that will bring results a hundred times more quickly than the efforts of the small breeder.

Sixteenth, the advantage of the sale of breeding stock to be acquired from the free publicity which is showered on all unique industrial enterprises.

In these sixteen functions there is ample opportunity for capital, backed by ability in organization, to reap an ample reward. Is it a dream? In a sense yes, but a dream made possible by the observation of the actual results achieved in similar lines, and of the present tendency in the poultry producing world.

Why has not this thing been done before? Because no one knew enough to do it. Why did not the wonderful trucking regions develop earlier in the South, and why does it still take northern settlers, backed by railroad advertising, to develop the wonderful modern industries which enables every city dweller in the North to have strawberries in February and fresh vegetables any day in the year?

Why did the California fruit trade develop? Did anyone suppose forty years ago that the unsettled valley around Pasadena would ever produce one thousand dollars per acre in one year? These orange groves, too valuable for agricultural purposes to be used as town sites, were precarious experiments until the trans-continental refrigerator car and the California Fruit Growers' Exchange paved the way and put each day in every eastern and northern city just the quantity of oranges that the people could consume at a profitable price.

Mr. Harwood, in the World's Work for May, 1908, after describing the "City of a Million Hens," raises the question, "If in Petaluma, why not anywhere?" I would like to answer that question by saying that while anywhere is a little broad, the reason the industry has not developed elsewhere has been because of the diversion of interested capital towards impractical large individual poultry plants, manned by hired labor. Another reason has been the lack of the technical knowledge necessary to construct and operate efficient hatcheries.

The poultryman has been a disciple of the poultry papers and poultry fanciers of the day. The poultry papers and poultry literature has generally been supported by poultry fanciers and manufacturers of incubators, patent nests and portable houses. The good folks have vied with one another in complicating the business. They have built steam-piped houses, with padded walls and miniature railways with which daily to haul away the droppings. A few famous fanciers selling eggs at $10.00 per setting have made such business pay, but alas for the luckless investor in what the visiting poultry editor would style a "handsomely equipped modern poultry plant."

A few years ago a Government poultry expert paid a visit to Petaluma. He came back and reported, "It is a great disappointment, the methods are very crude." The case is most pathetic. Here was a man employed by the people to teach them how to make poultry pay. His carfare is paid across the continent that he might visit the only community in the United States where at that time any considerable number of people were making their living from poultry, and because he did not find lightning rods on the poultry houses, he came back with the look of Naamen who, when he was requested by Elisha to bathe seven times in the river Jordan, replied, "It is very crude."

Will Co-operation Work?

That magic thing, "Co-operation," while utterly lacking in the Utopian qualities with which the word artist paints it, is a decidedly bigger factor in American affairs than the average man realizes.

The chief difficulty with co-operation is that the manager, if not incompetent, has an excellent opportunity to be a grafter. In Europe co-operation in agricultural and mercantile enterprise is older and better developed than in this country. Perhaps the Europeans are less inclined to be grafters, but a more likely explanation is that the members of such associations as these have learned how to prevent and detect graft, just as our business men have learned to avoid losses from the dishonesty of employes. That this is the true explanation is substantiated by the fact that when co-operation once becomes established in this country, it succeeds even better than in Europe.

When the creameries were started in the West several years ago, there was much complaint of swindlers, fake stock companies, and co-operative ventures in which the manager absconded with the butter money. To-day more than half of the American creameries are co-operative and the number is constantly increasing. They are efficient and successful in every way, and to-day make the finest of butter and pay the highest prices to the farmer for his cream. But their way was first paved and the business developed by successful private concerns.

Co-operation is entirely feasible and successful where the people behind the movement have enough interest in the enterprise and good enough business sense to run the proposition as efficiently as similar private enterprises are run. The idea that co-operation must always result in a big saving is a misconception. Employes will not work any harder for an association than for a private employer, sometimes not as hard. Certainly no employee will work as hard for an association as he will for himself.

Why people should expect to buy out the grocery store and hire the grocer to run it and save money for themselves, is a thing I could never understand. But if there is some great waste that co-operation will prevent, as where seven milk wagons drive every morning over the same route, or where the market of perishable crops is glutted one day and starved the next, centralization, corporate or co-operate, will pay.

I know of no better way to impress the reader with American co-operation in actual practice than to quote from a brief account of the California Fruit Growers' Exchange.

The Exchange was founded upon the theory that every member is entitled to furnish his pro rata of the fruit for shipment through his association, and every association to its pro rata to the various markets of the country. This theory reduced to practice gives every grower his fair share, and the average price of all markets throughout the season.

Another cardinal provision of the plan was that all fruit should be marketed on a level basis of actual cost, with all books and accounts open for inspection at the pleasure of the members. These broad principles of full co-operation constitute the basis of the Exchange movement.

The Exchange system is simple, but quite democratic. The local association consists of a number of growers contiguously situated, who unite themselves for the purpose of preparing their fruit for market on a co-operative basis. They establish their own brands, make such rules as they may agree upon for grading, packing and pooling their fruit. Usually these associations own thoroughly equipped packing houses.

All members are given a like privilege to pick and deliver fruit to the packing house, where it is weighed in and properly receipted for. Every grower's fruit is separated into different grades, according to quality, and usually thereafter it goes into the common pool, and in due course takes its percentage of the returns according to grade.

Any given brand is the exclusive property of the Local Association using it, and the fruit under this brand is always packed in the same locality, and therefore of uniform quality. This is of great advantage in marketing, as the trade soon learns that the pack is reliable.

There are more than eighty associations, covering every citrus fruit district in California, and packing nearly two hundred reliable and guaranteed brands of oranges and lemons.

The several local Exchanges designate one man each from their membership as their representative, and he is elected a director of the California Fruit Growers' Exchange. By this method the policy-making and governing power of the organization remains in the hands of the local Exchanges.

From top to bottom the organization is planned, dominated and in general detail controlled absolutely by fruit growers, and for the common good of all members. No corporation nor individual reaps from it either dividends or private gain.

So far we have dealt almost exclusively with the organization of the Exchange, its co-operative aspects, and general policy at home. Equally important is its organization in the markets.

Seeking to free itself from the shifting influence of speculative trading, by taking the business out of the hands of middlemen at home, the Exchange found it quite as important to maintain the control of its own affairs in the markets.

For this purpose the Exchange established a system of exclusive agencies in all the principal cities of the country, employing as agents active, capable young men of experience in the fruit business. Most of these agents are salaried, and have no other business of any kind to engage their attention, and none of the Exchange representatives handle any other citrus fruits. These agents sell to smaller cities contiguous to their headquarters, or in the territory covered by their districts.

Over all these agencies are two general or traveling agents, with authority to supervise and check up the various offices. These general agents maintain in their offices at Chicago and Omaha, a complete bureau of information, through which all agents receive every day detailed information as to sales of Exchange fruit in other markets the previous day. Possessing this data, the selling agent cannot be taken advantage of as to prices. If any agent finds his market sluggish, and is unable to sell at the average prices prevailing elsewhere, he promptly advises the head office in Los Angeles, and sufficient fruit is diverted from his market to relieve it and restore prices to normal level.

Through these agencies of its own the Exchange is able to get and transmit to its members the most trustworthy information regarding market conditions, visible supplies, etc. This system affords a maximum of good service at a minimum cost. The volume of the business is so large that a most thorough equipment is maintained at much less cost to growers than any other selling agency can offer.

The annual business of the California Fruit Growers' Exchange amounts to over ten million dollars, and the Exchange handles over half the citrus fruit output of the State. Yet there are people who say co-operation in America will not work.

Co-operative Egg Marketing in Denmark.

I have discussed at length the work of the California Fruit Growers' Exchange, as the best example in the United States of the co-operative marketing of farm produce. We have thus far but little co-operative work in the marketing of poultry products. Canada has a few examples, but it is to European countries that we must go for a full demonstration of the principle of co-operation when applied to the products of the hen. In England and in Ireland co-operative efforts in the growing, fattening, and marketing of poultry and eggs are quite common. It is to Denmark, however, that we must go to find the most wholesale example of this truly modern type of business effort.

The Danes are co-operators in the fullest sense. They have co-operative creameries and co-operative packing houses. The Danish Egg Export Society is an organization, the plan and work of which is very much like that of the California Fruit Growers' Exchange.

The local branch of the association buys the eggs of the farmer, paying for them by weight. Collectors are hired to gather them at frequent and regular intervals, and are paid In accordance with the amount of their collections, but must stand the loss of breakage. Each individual poultryman's eggs are kept separate until they reach a centralizing station. There are a number of these central stations at which the eggs are carefully crated and packed for shipment to England.

The individual farmer is fined or taxed for all bad eggs found in his lot. This fine is deducted from his receipts and he has nothing to do but to submit to it or get out of the association. The latter he cannot afford to do because the association has its established brands and can pay him more for his eggs than he could secure by attempting to market them himself. As a result of this strict system of making the producer responsible for weight and quality of the eggs the Danish eggs have become the largest and finest in the world.

Although the writer firmly believes in the co-operative marketing of farm produce, and considers that the success already secured in this work is conclusive evidence of the practicability and desirability of co-operation, it would not be fair to infer that co-operation has entirely driven out private or corporate enterprise. Just as a goodly per cent. of the citrus fruit of California is still handled by private dealers, so in Denmark we find that nearly one-half of the eggs sent to England are handled by private companies. Let it be noted, however, that these companies maintain a system of buying on merit which enforces high quality that is not to be found where private buyers are without the spur of co-operative competition. Before co-operation entered the orange regions of California, the fruit was poorly packed and handled and the markets at times so glutted, that shipments of fruit sometimes failed to pay the freight, and this was actually charged back to the unfortunate grower. Co-operation has done away with this waste. In like manner the great loss from decomposed eggs and half hatched chicks is unknown to the egg trade of Denmark.

Corporation or Co-operation?

The community of farmers producing a large quantity of a single kind of product is the coming form of agricultural enterprise. Will this community be promoted by corporation or by co-operation?

Arthur Brisbane says, "As individual control of the Government has been superceded by collective control, so individual control of industries will be followed by collective control. That is the natural order."

Brisbane is right. The individual, or the corporation, which is an individual using other men's money, foreruns co-operation, because the individual knows exactly what he wants to do and the big group of individuals does not know what they want or how to do it until individuals have, by concrete successes, shown them.

When the creameries were started, co-operative creameries were unsuccessful and could not compete with privately owned creameries. The farmers have now become too wise to be "easy-marks" to the fake creamery promoters or to trust their butter sales to a comparative stranger and co-operation is a success.

Poultry communities cannot be made out of whole cloth by the co-operative plan. Private corporations will be necessary to launch these enterprises. When they have reached the stage of development now to be seen in Little Compton and Petaluma they are ready for co-operation.

I have emphasized the point that the private corporation is the natural forerunner in this matter in order to discourage premature or over-ambitious efforts at co-operation. Whenever a community of poultrymen or, for that matter, a community of growers of any perishable form of products, who are already successful in the producing end, wish to take up co-operation and will see that men are selected to manage it who will use the same precautions to guard against incompetency or graft that they, as individuals, would use in their own business, there is excellent chance of success.

Go slow. Do not expect to get rich quick by "cutting out the middleman's enormous profits," for the middleman's profits are not enormous, and if you see that your co-operation is not paying, give it up and confess to yourselves that you do not know as much about the business as your private competitors.

That poultry should be kept on every farm to supply the farmer's own table does not permit of argument. When it comes to production for market, I believe there are some sections where it costs more to produce and market poultry and eggs than is received for the product when sold. For illustration: On a farm which is twenty miles from town and where grain cannot be profitably grown, the cost of teaming grain from the railroad station and of sending the eggs to market as frequently as is necessary to have a wholesome product, would certainly eat up all possible profits.

The farmer thus located would find a more profitable use for his time in some industry where the raw material is near at hand and the product needs less frequent marketing.

Some Poultry Geography.

When we are discussing poultry on the general farm, the problem of location is not to be taken into consideration, save to the extent that there are a few localities where food cost is so high or marketing facilities so poor as to make even the usual farm surplus unprofitable.

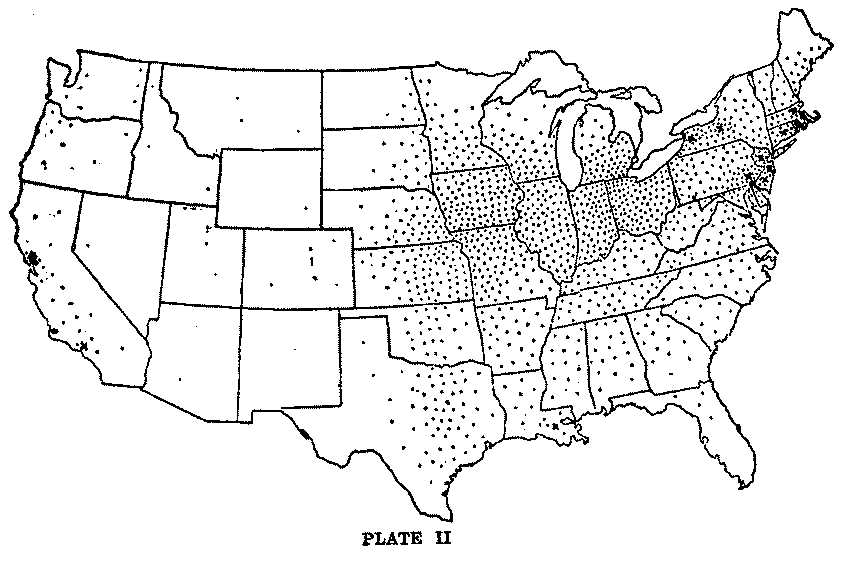

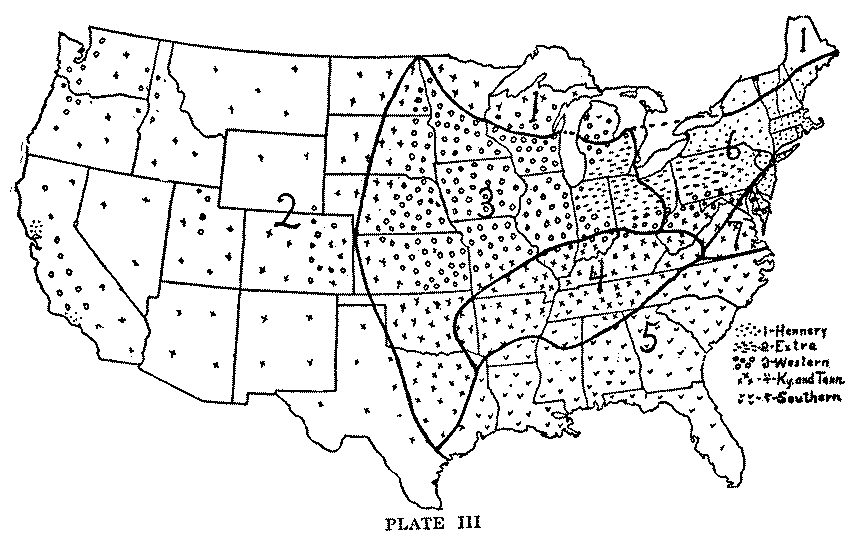

The map on page 45 shows the intensity of egg production and also indicates the location of the more important localities where poultry plants have succeeded. The map on page 47 shows the quality of eggs coming from various sections, which indicates pretty closely the general development of the poultry industry. These indications, however, are of little value in locating a poultry plant, for they refer to the poultry product on the general farm, and are a matter of the number and general intelligence of farmers, rather that a sign of the suitability of the locality for the poultry industry.

For purposes of discussion, I have divided the United States into seven sections as shown by the dotted lines on the second map.

Section 1 is the North Woods and too cold and remote for the poultry business.

Section 2 includes the great West, of which an adequate discussion is out of the question. Of course, the great majority of this area is too remote from markets for poultry production. The locations around the big cities in this section are excellent for poultry farming, as they are so far removed from the great farm region that their bulk of imported eggs are of necessity somewhat stale. California is good chicken country. The Puget Sound country is rather too damp. In the interior western regions the chicken business has not done well, chiefly because the atmosphere is too dry for the methods of artificial incubation attempted.