Chapter 11: Floppy disk drives

The first and most important thing:

Do not stick a working disk to uncertain drive. Review the drive before.

In many cases you will find seriously damaged 3.5 and 5.25" drives. Some of them

can be repaired. Many not.

Let's look at typical drive's parts:

If the drive has a belt mechanism, check its condition. Does the belt move

without spinning motor's hub or spindle? Maybe it needs to be replaced. Check

does the motor's hub spin easily - sometimes a drop of grease may be needed to

motor's bearings.

The exception there is a belt-driven Siemens 3.5" notebook drive. If motor fails

in it, it will never get stable rotary speed back.

If there is an integrated on-board motor, you don't have much field to move.

Check does it spin and does the disk hub rotate smoothly.

To apply a drop of lubricating oil into bearing (use REALLY SMALL amount of it),

use a syringe with needle. While filling, oil goes slowly inside and while

applying it goes slowly too. Needle allows to reach difficult areas near

rotating shafts or bearings.

There is one more problem with spindle motors in 5.25" drives: Sometimes,

especially in cheaper drives, the upper part which presses the disk to hub may

be out of center. Then after extensive use part of it wears off faster, so it

locks in the metal hub. Even if you polish it to become uniform, it may still

lock or loose pressing force which keeps the disk in place.

Head stepper motor

There are many designs of stepper motor driving head carrier. In 5.25" drives

the most popular is using metal belt which rolls off the motor's hub and pushes

the head carrier. This is quite rigid design and the only thing causing problems

there is bad motor or jammed carrier. Other designs include flat disk with

spiral engraving (in which typical problem is dust covering this engraving), or

screw mechanism (popular in 3.5" drives).

Screw mechanism needs lubrication. If there is no lubrication on a screw, add

some, but not too much.

Usually you will be able to move the head carrier by rotating the motor's hub.

The only exception is in 3.5" drives with screw mechanism, in which forces are

quite big relative to size of the screw. If carrier gets stuck, it means that

there is a problem with carrier track rods or mechanism. Clean everything from

dust and apply a bit of lubricant on shiny carrier track rods.

Solenoid is a mistake.

If the drive has a solenoid for dropping heads on the disk, you should know that

this drive won't last for too long. The solenoid introduces relatively high

vibrations right into heads assembly, slowly knocking them out of alignment. It

is possible to re-callibrate heads, but it is a slow and painful procedure.

Avoid such drives.

Here we end with mechanical part. Below you can see a typical

5.25" drive (with a solenoid, the purple thing in lower-left part) with

important parts marked. Not all drives look this way, most have no solenoid.

OK, let's begin:

A - Stepper motor shaft - may require cleaning/lubrication if

motor doesn't move well.

B - Two silver head carrier rails - may require cleaning and

lubrication if head carrier stucks.

C - Head carrier topmost rail for pull-down (solenoid or

lock-based) mechanism. Requires cleaning, rarely lubrication

D - The bearing under the bottom hub - in older drives may

require cleaning and lubrication, do it using a syringe with needle to reach it.

E - Top part of hub - requires cleaning, sometimes with

penetrating-lubricating solution like WD40.

F - Lock bearings - require cleaning.

Optical part

Optical part in many drives is quite rigid. Usually blowing with air and using

brush is enough, sometimes it may be needed to use a cloth with some cleaning

liquid which doesn't leave residues. In typical drive you may find the following

optical barriers:

- Detection of outwards track of the disk - near the head carrier

- Detection of inside track of a disk - sometimes present, sometimes not, near

the head carrier

- Index hole detector (5.25" drives only) - in the center, near hub

- Write protect tab detector (in 5.25" drives) - it sometimes serves as "disk

change" detector as disk during insertion crosses its ray.

- Format detector - in some rare 3.5" drives, format hole detector and write

protect tab detector are made with optical barriers, not mechanical switches.

Heads

Now it's time to clean heads. Do it at the end when no other dust will fly

inside the drive. I'm using a piece of cloth with window cleaning fluid. The

cloth is placed around a flat piece of metal which allows to reach heads. Do not

damage the alignment of heads in this step! Some drives may have oxide layers or

even water residues on heads, so clean them properly.

Some single-sided drives with head on the bottom allow to open upper part of

head assembly to clean head.

Heads alignment

The symptom of unaligned heads is simple: The drive fails to read the end of the

disk, first tracks may be read OK, and the same drive reads perfectly disks

formatted by itself. To fix it, you have to open the drive to have access to

heads, while drive is still connected to computer. You need also a disk

formatted on another, correct drive, filled to the last byte with some data.

So in MS-DOS, for example, try to read it, e.g. copy files from the disk to hard

drive.

"Sector not found?" huh?

Without removing disk loose upper head's locking screw (usually protected by

paint) and move the head a little. Fasten the screw a bit. Retry.

And again, and again... Usually "General fialures" mean that system has given up

and you need to restart the procedure from rebooting the computer. Alignment

made this way takes from few hours to few days. The proper procedure used in

repair workshops requires oscilloscope and special alignment disk which cannot

be made in a normal PC.

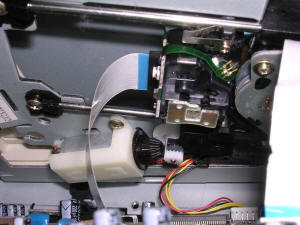

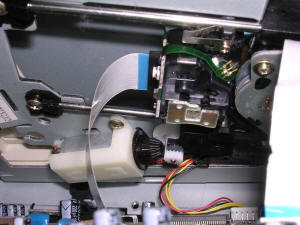

In some floppy, "floptical", magneto-optical or CD drives, a gear

rack mechanism is used instead of belt one. In the picture on the right

you can see such mechanism in old 32X CD drive. The motor drives the

gear by conical transmission, the gear pushes or pulls the rack which is

connected to the laser. These mechanisms work well for yaers even

without lubrication, but it is important to check do such meahcnism move

at all.

The common problems are linear bearings and driving shafts, they

sometimes need lubrication.If any mechanical drive was subjected to

atmospheric conditions (read: water, humidity, rain) end switches should

be checked with "beeper" tester and if they fail they should be cleaned

with alcohol (small end switches only need spraying it inside). In such

cases all connections should be re-seated and all optical barriers well

cleaned. Window cleaning fluid with alcohol is usually sufficient to

remove results of atmospheric exposure from these components. Be sure to

dry them well before testing. |

|

MCbx, 2016