Chapter 9: Monitors and displays

The goal of this page is not to show all possible problems with

monitors and displays because there is a variety of designs. It shows only

common and the most important problems with displays.

When you open a monitor, the same precautions that in computer's PSU apply.

Another important thing is high voltage part. In some very old displays, CRT

transformer-multiplier module has no bleeder resistor. It means that >10

kilovolts may be present in multiplier's capacitors when monitor is turned off.

Wait long enough or make some

discharging tool.

Prepare for lots of dust, as CRTs are convection-cooled.

The history that HV from transformer may instantly kill you is usually

exaggerated as current is relatively small and frequency is high. The problem is that if you get

shocked with HV, your hand may get into parts which are under lower voltages,

but with more dangerous currents (e.g. power supply unit's capacitors charged to

400V), and this part is the most dangerous one.

|

Cleaning

Cleaning the screen should be done using a soft cloth and window

washing liquid. Do not separate CRT from the casing unless you want to replace

it. If possible, you can remove plastic rear casing and clean it with water.

Casing should be cleaned as all plastic parts.

Inside, you will find lots of dust. Electronics part is located on

the bottom, hot air goes upwards, taking all dust from the base and rear

of monitor. This dust then falls down on electronics board and CRT like

in a cyclone filter. As always a small brush can be used, but pay

attention to tuning rings and magnets on CRT. If it is not enough and

you are sure that there is no high voltage retaining in capacitors, CRT

may be gently cleaned with a soft cloth. Do not move or remove the

rubber high voltage connector to the CRT as it may fall apart. Because

quite high frequency goes there, even a good insulation may cause HV to

leak. Deflection part can be cleaned using brush.

If monitor has a fan, you may see a picture like on the right - here not

only a brush, but a vacuum cleaner had to be used to clean this mess. |

They may be really dirty... |

If you encounter any problems, check tuning knobs first, also these on

the rear of monitor. If you experience lack of some signal, check the plug and

cable first because many times damaged wire in cable was the cause of all

problems.

Generally avoid manipulation of internal components when the

monitor case is opened and CRT is in operation. It is not only about possible electric shock, but some

regulators shouldn't be tuned when the unit is on.

Monitors have their own power supply units, giving relatively

high output voltages (usually >30V). If it works and transformer works, you

should hear HV transformer working.

Move your hand close to CRT screen face. If you feel static electricity it means that

HV section works.

If you see a horizontal line, it means that vertical deflection

is defective. Vertical line means that there is a problem in horizontal

deflection circuit. If you see a point, then something is really bad as

deflection doesn't work at all.

Technical solutions used to keep deflection are different in

different monitors. Sometimes it can be even linked to power supply unit

switching transistor, so diagnosing in such cases is very difficult. In

late-1980s displays you may find deflection built on some kind of TDA chip which

application you may easily find on the Internet and compare with your unit.

| During re-assembly remember that cables are usually separated.

High-voltage cable (going from transformer-multiplier to CRT plug)

should not be surrounded with sensitive signal or audio cables as high

frequency will leak.

In some color CRTs, especially in these with early iMac or eMac computers,

you may find purple distortions on screen. These distortions are caused by

magnetic field from speakers, slowly magnetizing the CRT. The only way to fix it

is demagnetization of a CRT. You won't do this easily with soldering iron as

with tape recorders, you usually need quite powerful coil connected to AC to

make this work.

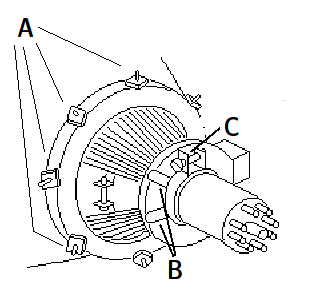

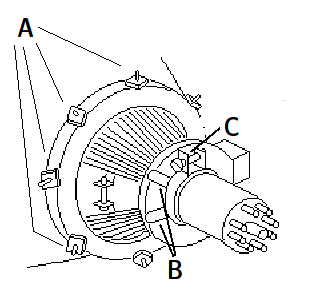

In a monochrome display, if a picture is warped on one edge, look at the

deflection circuit magnets located in the outward part of deflection coils

closest to screen (A in the picture). Are they set as in factory (they are usually protected with

paint or glue)? Maybe they were moved. Significant problems with picture center

is caused by bad orientation of centering rings (B in the picture). Keep front

one steady and move the second one slightly.

If a picture is rotated, check are deflection coils in proper angle. In some

cases the glue they are sticked to tube may peel off and coil assembly may

rotate by itself. In such cases to prevent destroying CRT avoid using excessive

force when locking the coils on CRT by screw ring (C in the picture).

If the monitor doesn't start and you see a very bright, blue or violet light

from the electron gun part of CRT (by default it may glow a bit in orange), it may be the symptom of irreversible CRT

damage: loss of vacuum. |

|

If picture is out of focus, try to tune the focus using focus trimmer located

on or near high voltage transformer. Sometimes there are two trimmers on a

transformer assembly. They mayh be for horizontal and vertical focus (tune them

one after another to get best results) or focus and "Screen" trimmer. Screen

trimmer sets the brightness of the picture, so if it is bright, or dark to loss

of colours it means that this trimmer is not well set.

These things were essential. There is an exhaustive

CRT monitor repair FAQ in

the Internet. It is mostly about PC monitors repair, but many things can be

applied to all CRT monitors and sometimes TVs. There is also a nice explanation

how CRT works.

Tuning

With years of operation, all electronic devices slowly change their

parameters due to components worn-out or work conditions changes. In CRT monitors it can be seen by picture being larger or smaller

than when monitor was new, picture may be shifted or moved. Sometimes picture is

too bright or too dark. It needs tuning. First, try with controls which are on

monitor's casing, as in many types everything can be done with them. But

sometimes external controls are limited co contrast knob and monitor needs to be

tuned using internal trimmers. Usually you won't find instructions for tuning

all monitors, especially for all trimmers on its mainboard. If you have a

schematic, you may figure out what potentiometer is responsible for what, but

many times schematic is not accessible.

You can use trial and error when looking for the proper regulators, but with the

following rules:

0. There is a high voltage inside. Tune the "live" system only when

tuning knobs are accessible by e.g. holes in casing. Do not stick fingers or

metal tools into a jungle of wires in a working monitor. Do not stick the

screwdriver blindly into working monitor's rear being in front of screen. Use the

mirror to view result while still having an eye on the electronics. There is

also a high frequency inside, so moving some wire closer to HV wire may have

impact on quality as the wire will pick the radio noise up.

1. Do not use trial-and-error when discovering regulation instruments of a

colour monitor. They have much more knobs inside and the final effect is visible

only after few other changes - they influence each other. This is way too

uncontrollable.

2. Do not try the regulation instruments swinging them from one limit to another

- just move them very slightly and effects should be visible, if not, don't use

force, but restore them. If something doesn't move or is locked by paint or

piece of rubber, don't move it as it may be critical for condition of a circuit.

2. For tuning picture width, usually a coil is used. You stick a plastic

screwdriver in and turn the core sliding it in or out of the coil. Use the

plastic screwdriver during live-tuning as metal one will: a. already influence

the picture and b. heat itself up by inductivity, sometimes even melting the

plastic part of core.

3. Typical FAQs deal with problems of too dark monitor. Sometimes it becomes too

bright. If monitor is still too bright after turning brightness to minimum,

there are two things frequently skipped in FAQs:

- Grid voltage on CRT. It is usually regulated using a "SCREEN" or "G2"

trimmer on (or in smaller monitors near) flyback transformer-multiplier

assembly. Simplified, this controls how much electrons will be "pushed" towards

screen. The problem with this trimmer is that sometimes it gets worn out and

requires small correction to get away from "milky" picture.

- Heater voltage/currrent. Heater may be connected through the

low-resistance resistor which, contrary to typical resistor when failing, may

become more conductive. This is a common problem for all portable TVs from

eastern block countries such as Elektronika or Leo. The problem is that the heater is powered using a complex high-frequency current flowing from

HV transformer as a side-winding and you won't measure the voltage very

precisely with typical non-TrueRMS multimeter.

Another thing is with LCDs. LCDs of old computers usually have 4 problems:

1. Crystal poured out or screen rot

Impossible to repair, visible by black patches on screen caused by liquid

crystal particles poured from their chambers. Screen rot, seen as usually

circular wet-like patches, is caused by cleaning LCD with aggressive chemicals

e.g. alcohol and cannot be fixed as it's the sign of internal delamination.

2. Poor contrast

In most cases it cannot be easily fixed. In some other it is possible to boost

parameters using internal trimmers. Do not try to modify them without knowledge

what are you doing

3. Missing lines

In low-resolution displays this problem may be fixed by gently pressing LCD on

the edges. Sometimes it may be needed to remove the LCD part from its circuit

board and clear the conductive rubber, but it may be difficult to put it back

together. Check connectors and ribbon cables as problems with them may be

indicated by filled or empty lines on the screen.

4. White seen as red, red backlight

Problem with backlight tube. The only solution is to carefully disassemble LCD

enough to remove tube and then install the same one. Be careful as tube is

usually extremely fragile. In some rare cases red tube

is symptom of bad inverter, but usually bad inverter shuts off itself (or blows

its fuse) and doesn't start up while in bad tube case the inverter shuts off

after some short time.

MCbx, 2016