Teardown of a Greenlite 8W LED light bulb

(Last modified

15 Jul 2012)

On a recent trip to a local hardware store, I saw a stack of Greenlite

120 VAC LED lightbulbs, marked at $6 for a box of two bulbs. The

package clained the bulbs provide 450 lumens, which was advertised as

the equivalent of 40W bulbs; plus, the bulbs are dimmable.

Naturally I had to pick up a few. Naturally, I also had to tear

some apart.

Before I start with the teardown, I should mention that these bulbs are

brighter than I expected and work well with a dimmer. I replaced

some 60W frosted incandescents with these LED bulbs, in my office

ceiling light fixture. The LED bulbs' light is as bright

(subjective, I know) as the original bulbs and I like the 3000K

temperature better. Since they are LEDs, they produce far less

heat than the original incandescents, which helps in the summer.

First, the warnings!

This teardown involves breaking the bulb's glass and working with

exposed broken glass. Wear eye protection and work

carefully. The bulbs contain some totally excellent LEDs, but

they aren't worth making mistakes or taking shortcuts and injuring

yourself. The instructions below worked for me, but you are on

your own for this teardown!

I started by using a pair of slip-joint pliers to crush the bulb's

base. This took considerable hand strength; get some help if you

need it. Another option might be to clamp the screw base into a

bench vise and crush it with the vise. My goal here is to crack

the screw base enough to free it from the plastic frame it is mounted

on. Note that I only applied enough strength to crack the seal

between the metal wrap (the part with the screw threads) and the

plastic frame above it.

With the screw base cracked free of the plastic frame, I used a spare

pair of wire cutters to slice away the plastic frame so I could remove

the screw base. There is a small section of PCB that sits inside

the screw base and has two small wires connected to the metal parts of

the screw base, one to the tip of the base and one to the metal

wrap. I simply tore these two connections off when I removed the

screw base.

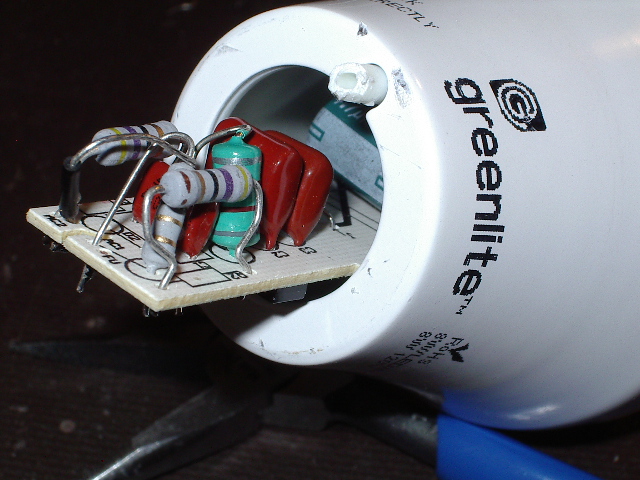

Here is the bulb with its screw base removed. You can see the

narrow end of the PCB with some power resistors on it.

Next, I put the bulb in a heavy plastic freezer bag, then tapped the

glass bulb with a hammer to shatter the glass. I was careful to

use the least amount of pressure needed, since the LED array is just

underneath the glass and I didn't want to damage that.

Here you can see the top surface of the LED array. There are 18

very large LEDs mounted onto a PCB underneath the white plastic shield

you see here.

I used a thin blade screwdriver and a hobby knife to remove the glass

shards. The glass is embedded in a silicone rubber compound that

seals the white plastic shield to the glass and to the bulb's metal

frame. I worked carefully on this phase to avoid injury while

removing the glass.

With the glass and sealing compound removed, I removed the three screws

you see above. This freed the white plastic shield, exposing the

LEDs and the PCB they are mounted on.

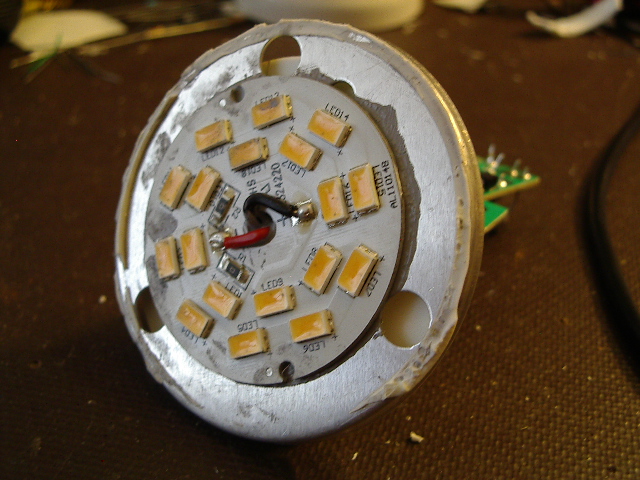

Here is a closeup of the LEDs on their white PCB. Note that the

PCB floats on a thin film of silver thermal compound, held in place

only by the tension of the red and black power wires you see in the

center of the PCB. You can see some of the leftover sealing

compound on the outer rim of the metal platform below the PCB; this

metal platform acts as the LEDs' heatsink.

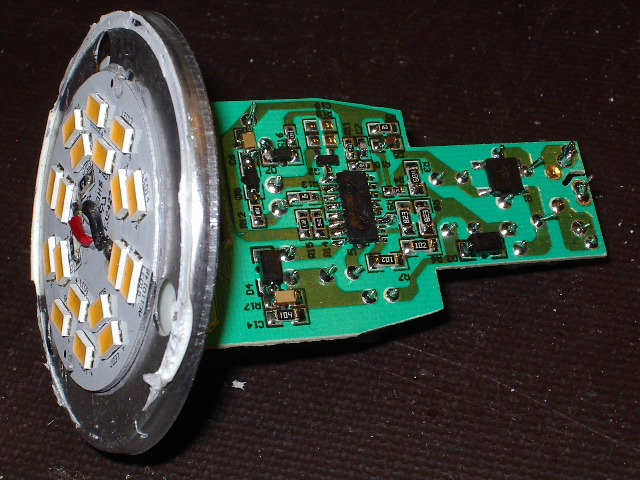

Here you see the LED PCB after some handling, as I was tracing out the

circuitry. The dark grey smudges are some of the heatsink

compound that I spread while handling the PCB.

Note that the black wire is soldered to a pad marked with a plus-sign

and the red wire is soldered to a pad with a minus-sign (between two

zero-ohm resistors). I verified with a DVM that the markings on

the PCB are correct; the pad marked with a plus-sign is connected to

the anode of the first LED in each string.

The LEDs are wired as two nine-LED strings; one string is LED1 through

LED9 and the other string is LED10 through LED18.

Summary

So I now have a small PCB, about 1.5" across, with 8

watts worth of very bright LEDs to play with. It will be simple

to repackage the PCB as a spotlight, garden light, or as a giant pixel

in a really big sign or art project. It would also be easy to

harvest the individual LEDs for use in smaller projects. Total

cost for two PCBs and 36 LEDs, six dollars and a bit of work on my

part. By the way, there are some pretty nice parts on the driver

PCB that are also worth harvesting.

Home