Chapter 3: Fans and cooling

An important part of any computer is cooling solution. Every electronic

component which draws some power dissipates excessive power in heat and this

heat has to be removed before temperature will rise to destructive levels. To

solve these problems, there can be two solutions:

1. Passive cooling, which is a heatsink installed on a chip.

Heatsink may be installed using screws, glue or thermal grease. Sometimes a

piece of metal foil is glued between heatcink and chip to make thermal

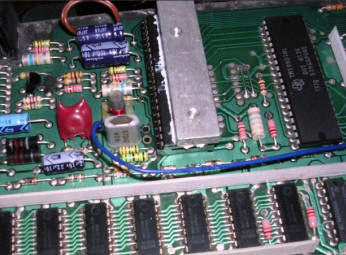

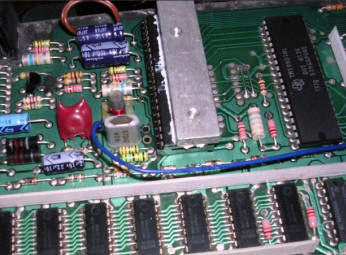

conductivity even better. In the picture below you can see two heatsink

solutions:

The first one is a piece of RF shield profiled that heat from chip

is absorbed by it and dissipated on its large surface. This approach is

widely used in Commodore machines.

The second one, seen for example in TI99 computer, use an alluminium

block. It may or may not be profiled in fins to get bigger dissipation

area. In this example it can be connected by screws to the rest of

casing to increase the area even more. Notice the thermal grease between

metal heatsink and chip surface. This is a white, sillicone-based

thermal grease, easy to get in electronic shops. In many old computers

it may be needed to replace this grease, especially if it became too

hard and brittle.

In some other cases conventional heatsink has one side fastened to metal

chassis. To remove an old grease, use toilet paper or paper towels. Now

apply a new thin layer. |

|

2. Active cooling is blowing (or pulling) air between components

to take the heat and remove hot air from the computer. In our world of 8-bit

microcomputers it is not widely used, but you may find fans in early 1980s

machines or especially large computers. In this case you will find lots of dust

in such machine. Then inspect the fan.

First of all, for what voltage is it? Some early machines may

use 230V AC cooling fans (like Robotron 1715) which rarely fail. Other ones may

use also AC fans, e.g. 125V AC with step-down transformer (Alcatel 7100). These

fans rarely fail. If they move with difficulty, you usually only need to put a

few drops of lubrication (e.g. oil or WD40) into bearing which is in most cases

hidden under sticker. To avoid destroying sticker use a syringe with needle,

make two holes in a sticker and put the oil into one of them slowly rotating the

fan.

The most failing fans are DC brushless fans for e.g. 12V. These

fans use motor with rotating magnet ans a special circuit to activate different

coils pulling the rotor. So do not spin this fan too fast by hand,

because voltage induced in coils may destroy the electronics. To fix problems

with it you may do the following things:

1. Replace the fan with a new one - this works well when you

have a replacement fan.

2. As with AC fans, add some lubrication to the bearing. The

problem is that in many fans bearing is too dirty to be working properly, so...

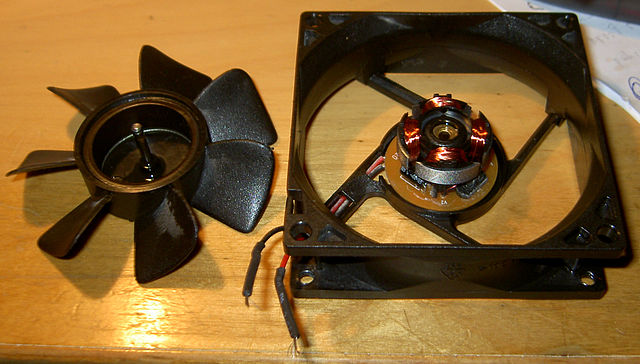

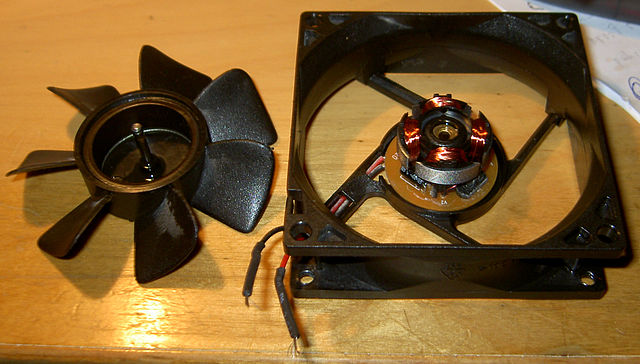

| 3. Disassemble and clear the fan. After removing the fan from a

system, this requires the following procedure: - Remove the

sticker using e.g. sharp knife. You will need it later.

- You will see a bearing with shaft locked by a small retaining ring.

Clear the outside of the bearing using brush and remove retaining ring

using a sharp needle. Do not break the ring, it is made of plastic.

- Now you can remove the rotor fan with magnet from its chassis. You can

even wash the rotor in water and dry it well.

- Clean the chassis with brush and cloth, clear the hole for shaft using

some thin nail and cloth. Do not use force here.

- After it dries, apply some lubrication to the top of shaft hole as well

to the shaft. Insert the shaft to the hole.

- Slowly spin the fan to see does it move well. Place the ring on a shaft,

then using two needles push it into the shaft's locking cut. If there is

still a problem with smooth spinning, apply some lubrication to the

bearing.

- Close the bearing using sticker you removed. This is important because

locking ring may fall off or excessive lubrication may go out polluting

the electronic parts. |

Source:

Wikimedia comons |

If the fan is only dirty, this procedure will restore it at

least for some time. The problem is when the bearing wears out on one side. This

damage makes the shaft swing in this worn out space making a loud noise. It

cannot be fixed any way.

MCbx 2016